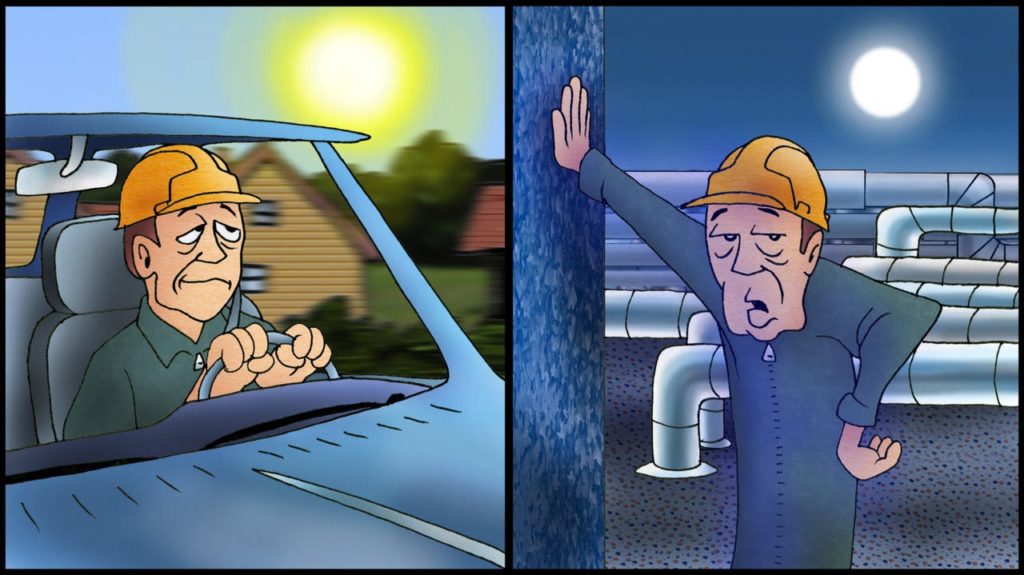

We have provided since 2011 and continue to provide monthly “managing fatigue” articles that correlate to the topics in our managing fatigue calendars. The purpose of this “Filthy Fifteen” article is to provide information about fatigue as a cause of errors and accidents, with particular emphasis on fatigue management during the novel coronavirus pandemic.

Control rooms that are subject to the PHMSA Control Room Management Rule are likely aware of a “stay of enforcement” that provides some relief from the hours of services (HOS) requirements. This is probably due to industry groups seeking permission for companies to deviate because they are planning to change schedules, requiring essential personnel to exceed the HOS, and/or considering other measures to staff control rooms.

Generally, fatigue contributes to errors and accidents after people have worked too many consecutive shifts without sufficient opportunities for recovery sleep. One Control Room Manager told me that some of their managers suggested going to 14 on, 14 off schedules instead of the usual schedule. Pipeliners are people of action, even if some actions might not be the best course. The Manager and I discussed other measures that might minimize exposures and ensure the control room was staffed appropriately.

While I have worked many shifts in a row once upon a time, 14 in a row is not something I recommend at any time. I have assessed schedules, using FAID fatigue modeling software, for the potential risks of fatigue. The results show, that the more shifts one works in a row, the more the potential risks of fatigue increase. While that is just common sense, common sense ain’t so common. I asked the manager who would be accountable if an accident occurred on any shift when people worked more than four in a row as they usually do. The best advice about shift schedules is to not change them unless it is absolutely necessary. If it has to be changed, do fatigue modeling to identify any additional risks. Then communicate those risks to those affected by the change.

The Health and Safety Executive published a seven page report to assist hazardous industries with decisions aboutstaffing issues and fatigue management. HSE Fatigue Now It provides guidance that might be useful to you. Here are some of the things I gleaned:

- Identify the safety-critical tasks that must be performed during normal, abnormal, and emergency situations.

- Identify the minimal staff levels that are necessary to perform those tasks.

- Identify any safety-critical tasks that can be delayed.

- Identify and administrative tasks that can be omitted, delayed, or eliminated.

- Ensure that adequate support staff are available at all hours to provide support when needed.

- Identify steps to be taken if the system had to be slowed down or shut down.

- Perform a “new” fatigue hazard analysis to identify new or different fatigue risks.

- Perform a “new” workload analysis to identify new or different workload factors such as stress, time pressure, mental demand, or physical demand.

- Communicate with all stakeholders, so they understand the changes, additional risks, and countermeasures they can take.

THE FILTHY 15 EDUCATIONAL PROGRAM | Charles Alday © 2020 Please Distribute to Others.