There is a statement in the PHMSA Control Room Management (CRM) frequently asked questions that is repeated in the inspection questions: FAQ D.09. PHMSA promotes the use of a fatigue risk management system (FRMS) as a tool for implementing fatigue mitigation. That is the extent of the guidance provided by PHMSA. If a company wants to use a FRMS as a tool, it will need to research what a FRMS is and how it can be used for fatigue mitigation. The purpose of this article is to provide additional guidance on the meaning of a fatigue risk management system (FRMS) and ways to develop and implement an FRMS in a pipeline control room. The goal should be to reduce the risks associated with controller fatigue from both schedule-related fatigue and task-related fatigue.

Some pipeline companies apply the guidance of “API Recommended Practice 755 Fatigue Risk Management Systems for Personnel in the Refining and Petrochemical Industries” that support their current practices even though parts of the guidance do not apply to pipelines and its hours of service do not match the PHMSA guidance on hours of service. It does outline some useful components of a FRMS.

I think the guidance for a FRMS from the International Civil Aviation Organization (ICAO) is better. Consider their definition of a FRMS:

A data-driven means of continuously monitoring and managing fatigue-related safety risks, based upon scientific principles and knowledge as well as operational experience that aims to ensure relevant personnel are performing at adequate levels of alertness.

The ICAO FRMS Implementation Guide for Operators (First Edition July 2011) provides guidance for:

- Science for a FRMS

- FRMS Policy and Documentation

- Fatigue Risk Management Processes

- FRMS Safety Assurance Processes

- FRMS Promotion Processes (including Training and Education)

- FRMS Implementation

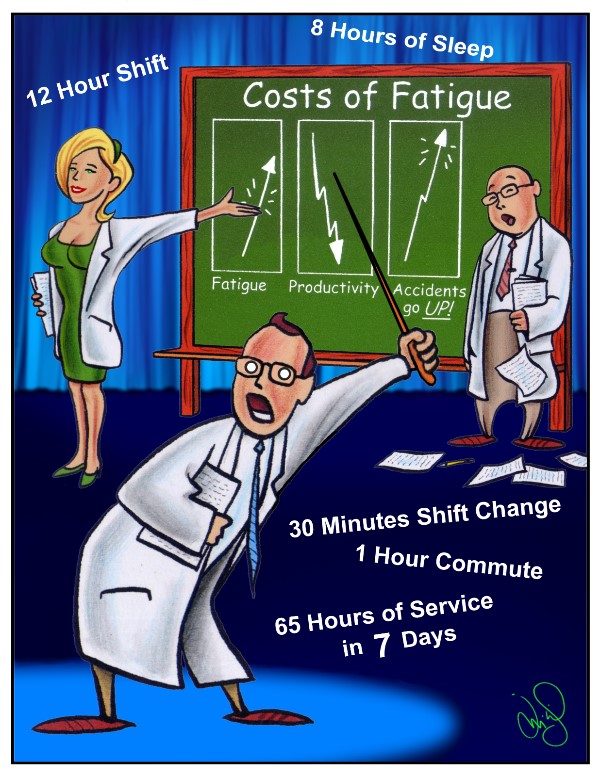

When we develop a FRMS, we consider the science related to sleep, fatigue, circadian rhythms, and shiftwork. One of the tools we use is FAID® fatigue modeling software that is based on scientific research and provides a data-driven means of analyzing shift schedules and hours of work. A fatigue hazard analysis can be performed to determine the risks of a fatigue related incident based on a particular control room’s practices, environment, and schedule. If a FAID hours of service diagnostic is performed monthly based on the planned hours of work versus the actual hours of work, that data can be used for continuous monitoring using both scientific knowledge and operator experience. One of its benefits is that it can include the numbers in this month’s illustration: hours worked, commute time, shift change time, off duty time, and hours worked for the past seven days.

In order to reduce the risks associated with controller fatigue, it is necessary to identify the risks. That is one of the PHMSA inspection questions: D0-1: Does the operator’s fatigue mitigation process or procedures (plan) identify operator-specific fatigue risks? We include a list of company-specific fatigue risks and then address, within the FRMS, how those risks are reduced. Does your fatigue management plan identify and mitigate fatigue risks such as?

- A fatigue-related occurrence commuting to and from work

- A fatigue-related occurrence during shift change

- A fatigue-related occurrence during the first hour on shift when checking out the system and planning the tasks during the shift

- A fatigue-related occurrence during communications with others at any time during the shift

- A fatigue-related occurrence while monitoring at any time during the shift

- A fatigue-related occurrence during an abnormal or emergency event

- A fatigue-related occurrence due to sleep problems or other health issue

Your company’s FRMS risk management and safety assurance processes should include emphases on the risks of drowsy driving, professional shift change practices, procedures for system checks, operational communications practices to minimize errors, alertness techniques during times of shift when people are susceptible to fatigue, abnormal and emergency operating procedures, and company policies that provide health screenings for sleep disorders. These emphases can take place through annual fatigue training and ongoing education. However, that is no substitute for rigorous processes and strong procedural requirements.

The pipeline industry is beginning to emphasize the importance of safety management systems. A FRMS is a safety management system for managing fatigue and should be integrated into company safety management systems or safety programs. While the CRM procedures apply to pipeline controllers in control rooms, I have more concerns that pipeliners who work in the field are more subject to fatigue than controllers. They work outside in all types of weather. They drive long distances between facilities. They may work long hours and are subject to call outs at any time of the day or night. Controllers or others who need advice on an equipment or technical problem sometimes interrupt their sleep. Prudent pipeline company executives would include all operational and SCADA employees in their FRMS and their safety management system. What is your company doing to address the potential fatigue risks for employees outside of the control room? Fatigue of any employee at any position in the company can affect productivity, profits, and safety.

Charles Alday © 2015 Please Distribute to Others.