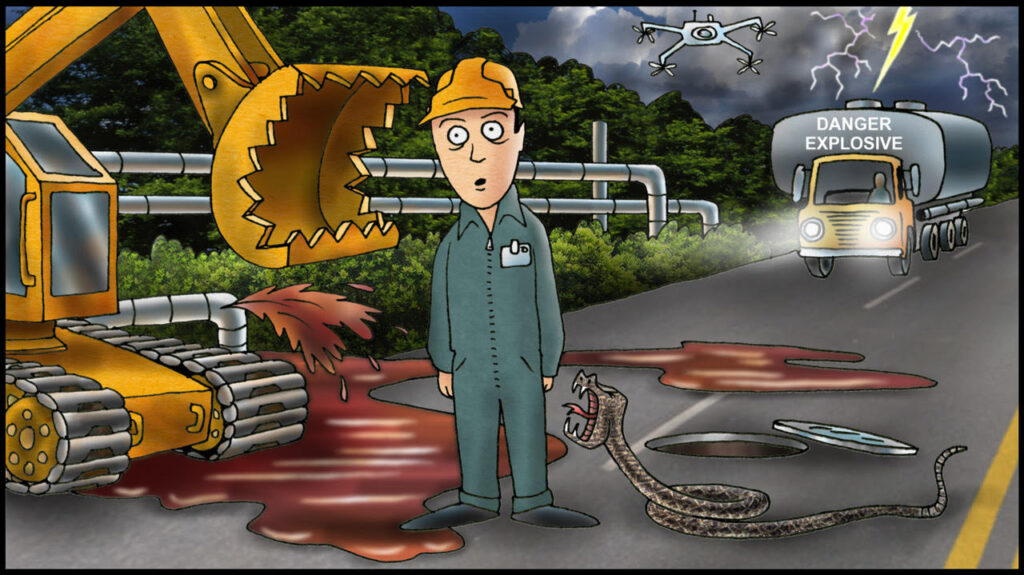

There are several factors that contribute to Lack of Awareness. Have you ever been in a situation where you had to pay attention to one thing? Did you also pay attention to other things in the area to ensure your safety? I used to teach people to create a “safety zone.” Yes, they had to pay attention to what was right in front of them. They also needed to be aware of what was behind them, to their left, to their right, above them, and below them. I even illustrated by singing part of the spiritual “Standing in the Safety Zone.”

The Health and Safety Executive of Great Britain offers an easy to apply tool for addressing Lack of Awareness. It is the SLAM Technique.

STOP – Engage your mind before your hands. Look at the task at hand.

LOOK at your workplace or work area and find the hazards that might harm you or others. Report these to your supervisor and teammates.

ASSESS the effects that the hazards have on you, the people with whom you work, the pipeline or equipment, the environment or the public. Ask yourself if you can perform the task safely. Do this with your supervisor or teammates.

MANAGE – If you feel unsafe, stop the work. Determine what actions are necessary to mitigate the hazards and make the situation safe. Work with others to apply those actions in order to create a safety zone.

In a control room, adequate situational awareness requires that the Controller is able to accurately and reliably within the available time address the condition and behavior of the pipeline in normal, abnormal, and emergency situations without reliance on support. This is a reason the Control Room Management regulations require that Controllers be provided “adequate information.”

Our usual process of explaining situational awareness involves these elements:

- PERCEIVE all the necessary, available information and critical factors that are sensed and mentally combine the indications.

- COMPREHEND the meaning of what is perceived by analyzing and diagnosing the relationships of the information and your operational goals.

- PROJECT what is comprehended into correct actions and reactions in the present and how those actions affect what will occur in the near future.

Apply that process to a startup of a pipeline. What must one perceive, comprehend, and project? What are the indications of normal operations? What would be the indications of an abnormal situation? What would you do?

Some of the other Filthy 15 can contribute to Lack of Awareness. Complacency, Distractions, Fatigue, Pressure, and Stress might contribute to Lack of Awareness. How might Inability to Admit Limitations, Lack of Communication, Lack of Knowledge, Lack of Resources, Lack of Teamwork, and Norms affect your awareness? For example, a Lack of Communication between a Controller and a Field Technician about the status of a safety device might result in the Controller having inaccurate or missing information and thus an inability to develop adequate situational awareness.

For Lack of Awareness, use a self-questioning or “What-If?” attitude. Use effective shift planning and communication techniques, and perform as many critical tasks as possible early in the work day or on the work shift. If you do not understand something about a task, ask someone else. Successful people are willing to seek advice from others to prevent errors and accidents. Be aware that human beings have difficulties maintaining awareness and paying undivided attention.

THE FILTHY 15 EDUCATIONAL PROGRAM | Charles Alday © 2021 Please Distribute to Others.