Socrates supposedly said, “All I know is that I know nothing.” That is the quintessential Lack of Knowledge. I think he meant that he knew nothing compared to all that he could know. Most of us do not take that universal approach to knowledge, but specialize on a few subjects. I see job titles for “specialists”, and I guess that means people in those jobs know a great deal about a particular area of expertise. For most pipeliners, we need a general and basic knowledge of pipeline operations and maintenance to be successful at avoiding errors that lead to accidents. Consider these examples:

An operator was assigned to assist in a maintenance task. His assigned responsibility was to perform the necessary tasks to receive and to remove nitrogen-laden gasoline and three pipeline pigs from the line. This facility had recently been equipped with a programmable logic controller (PLC). The operator did not have the necessary knowledge to perform the assigned tasks at the facility using the PLC. The tasks were performed incorrectly and the timing for a product switch from one product to another was late. Product was contaminated and this affected costs and customer satisfaction.

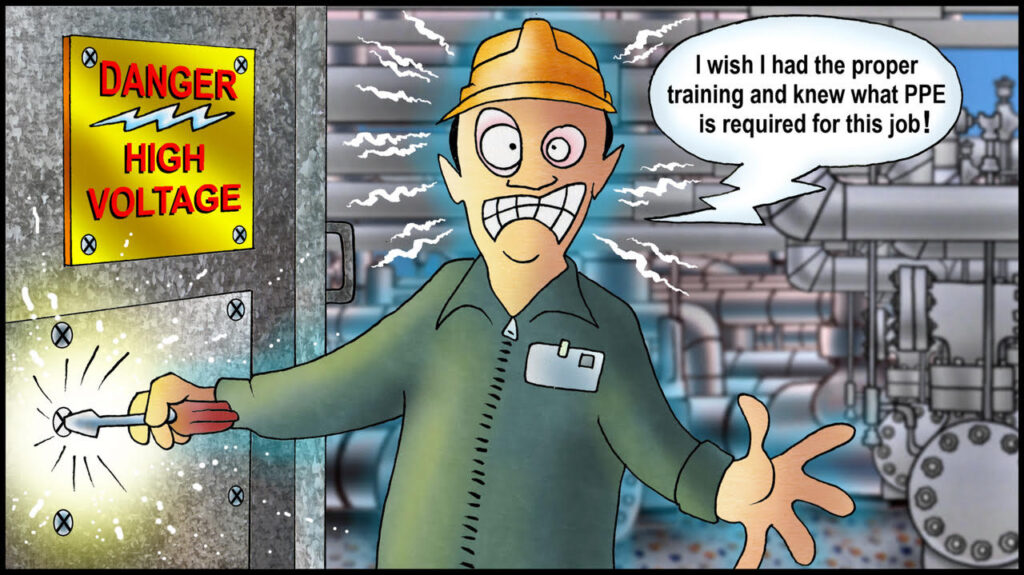

A group of maintenance technicians was going to perform preventive maintenance on high voltage electrical breakers. Some were experienced; others were inexperienced. The required hazard analysis was performed inadequately and incompletely. There was lack of knowledge about the procedure, the safety requirements, and the equipment. Some of the technicians did not have the necessary knowledge to perform the tasks safely. One of the breakers was not locked out, resulting in an electrical flash, equipment damage, and a personal injury near miss. Injury was prevented because the employee was wearing personal protective equipment.

A Controller was controlling and monitoring a hazardous liquids pipeline using a SCADA system. He was filling a tank at a terminal. He received a high-high level mechanical alarm but did not shut down the pipeline because the radar gauge showed an abundance of working capacity in the tank. The tank overflowed. The Controllers were not aware of the way each specific tank alarm worked.

This tank had a gauge tube that was fitted with an electronic radar level gauge and the tank was fitted with a high-high mechanical alarm. This is critical because the Controller said if he had known that the high-high level alarm was a physical – mechanical alarm, he would have performed differently.

What would you do if these incidents happened at your company? Would you “blame and train” or take a critical look at your basic operations training program and ensure it provided adequate knowledge, understanding, and practice to all personnel?

What examples do you have from your company when lack of knowledge led to an incident? If they occur regularly, you need an error management program that identifies the causes.

For individuals, consider these actions to fight lack of knowledge:

- If you do not know how to perform a task, do not perform it.

- Don’t allow pride to tempt you to get the job done.

- Ask someone who knows to show you the correct way.

- Seek to perform actual tasks or simulate or drill on normal, abnormal, emergency, and maintenance tasks.

- Always be learning, whether you are inexperienced or a veteran.

THE FILTHY 15 EDUCATIONAL PROGRAM | Charles Alday © 2021 Please Distribute to Others.