Many 24×7 high-risk industries, including rail, aviation, pipeline, emergency services and healthcare, struggle with balancing safety, productivity and worker well-being. It should be no surprise that fatigue contributes to the complexity of this balancing act. For pipeline companies operating in the U.S., PHMSA requires that all operators implement methods to reduce the risks associated with Controller fatigue that might interfere with the ability of a controller to carry out defined roles and responsibilities. At a minimum, companies operating pipelines in the U.S. must:

- Establish shift lengths and schedule rotations that provide controllers off-duty time sufficient to achieve eight hours of continuous sleep;

- Establish a maximum limit on controller hours of service (HOS), which may provide for an emergency deviation from the maximum limit if necessary for the safe operation of a pipeline facility;

- Educate controllers and supervisors in fatigue mitigation strategies and how off-duty activities contribute to fatigue;

- Train controllers and supervisors to recognize the effects of fatigue.

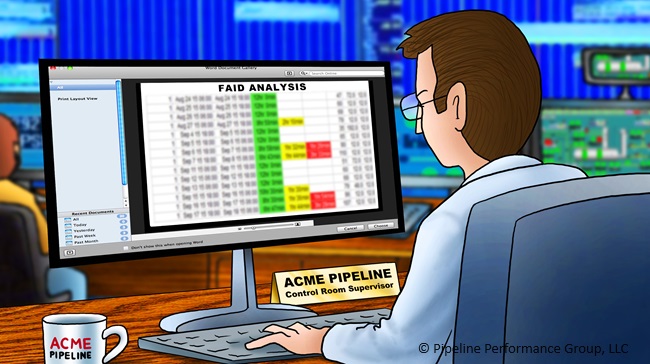

Additionally, the operator’s fatigue mitigation plan (preferably fatigue risk management system (FRMS)) must adequately address how it reduces the risk associated with controller fatigue. An FRMS should demonstrate a scientific foundation for the provisions of the plan. Pipeline Performance Group and some pipeline companies analyze fatigue risk exposure using assessment tools, like InterDynamics’ FAID Quantum, GRAID FRMS, and HAZAID to identify fatigue exposure and support fatigue management.

FAID Quantum uses biomathematical modelling to evaluate shift schedules for potential fatigue risk, showing times during shifts when Controllers are most likely to be fatigued, for comparing one shift schedule to another and for building FAID scenarios based on different overtime situations. GRAID FRMS provides a tool that grades the adequacy of current and future fatigue safeguards. HAZAID is used as part of a Fatigue Hazard Analysis (FHA) to record fatigue hazard scenarios, assess the risk and formulate controls to mitigate the risk.

In combination with the monitoring of hours of service and the avoidance of deviations, the results of these analyses can help companies and individuals understand the risks of fatigue. Understanding the potential risks posed by the shift schedule and overtime shifts can help encourage individuals to use their off-duty time for sleep and rest, and to seek medical help for sleep problems.

We are often asked which shift schedule is ‘the best’. Charles Alday always had the answer – “it’s the schedule your control room is NOT working!” There is no single answer to this question because each control room is different. Among other information, an analysis reviews current staffing, current workload, commute times, shift lengths, schedule rotations, deviations from HOS limits and fatigue countermeasures when evaluating the most suitable scenarios for an organization.

Do your due diligence. Conduct a fatigue hazard analysis or engage a company like ours to help you. The results will improve your situation awareness and decision making when it comes to considering alternate shift schedules, shift rotations, Controller staffing and identifying the times during a shift when Controllers are more likely to be fatigued. This information is key to providing effective fatigue countermeasures.

MANAGING FATIGUE EDUCATIONAL PROGRAM

Christina Via © 2024 Please Distribute to Others.